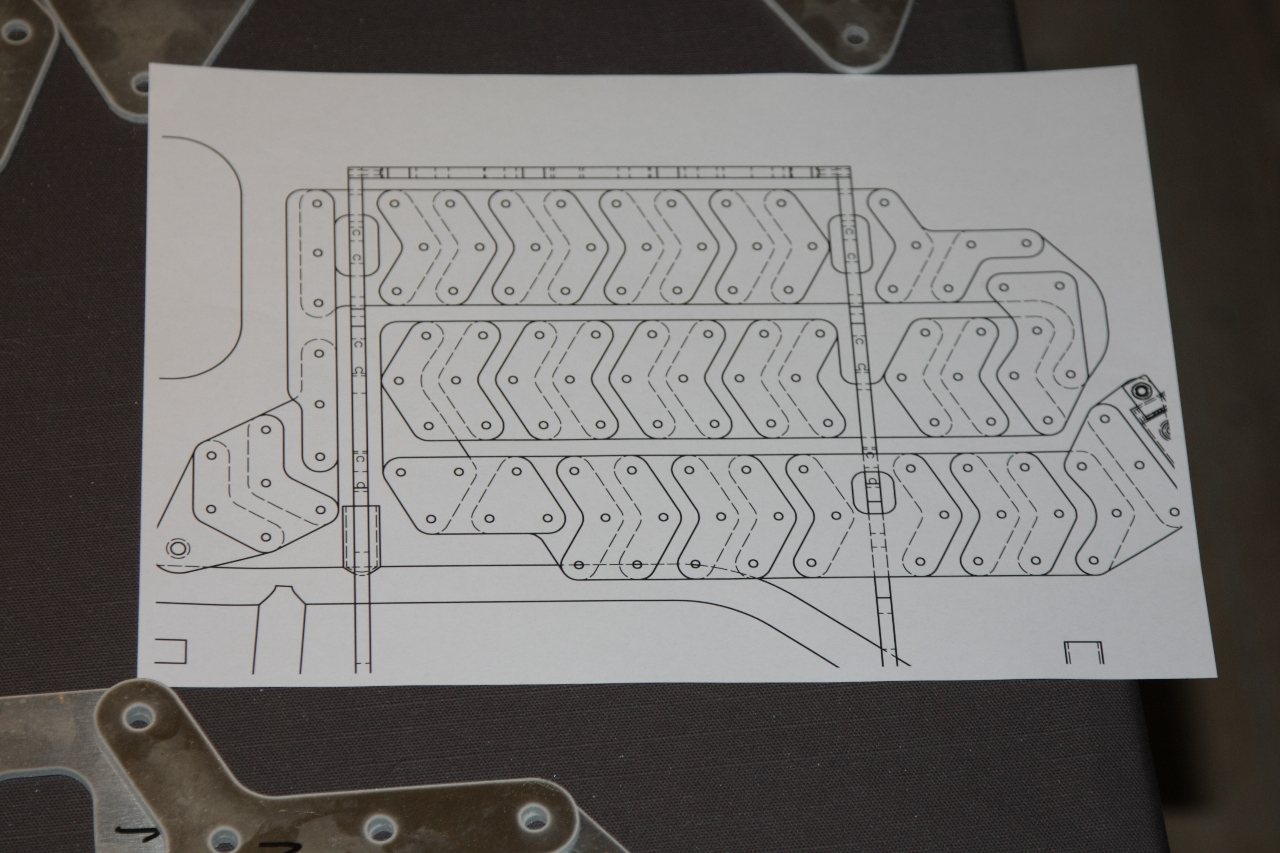

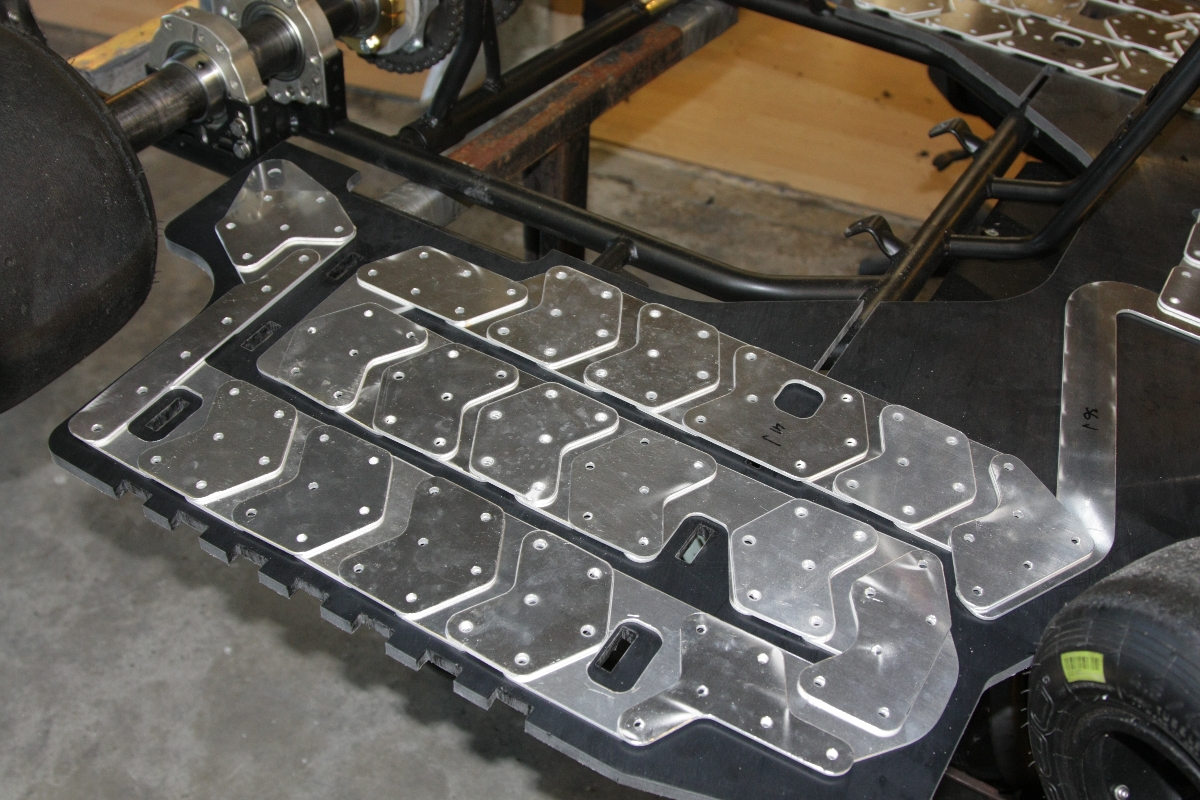

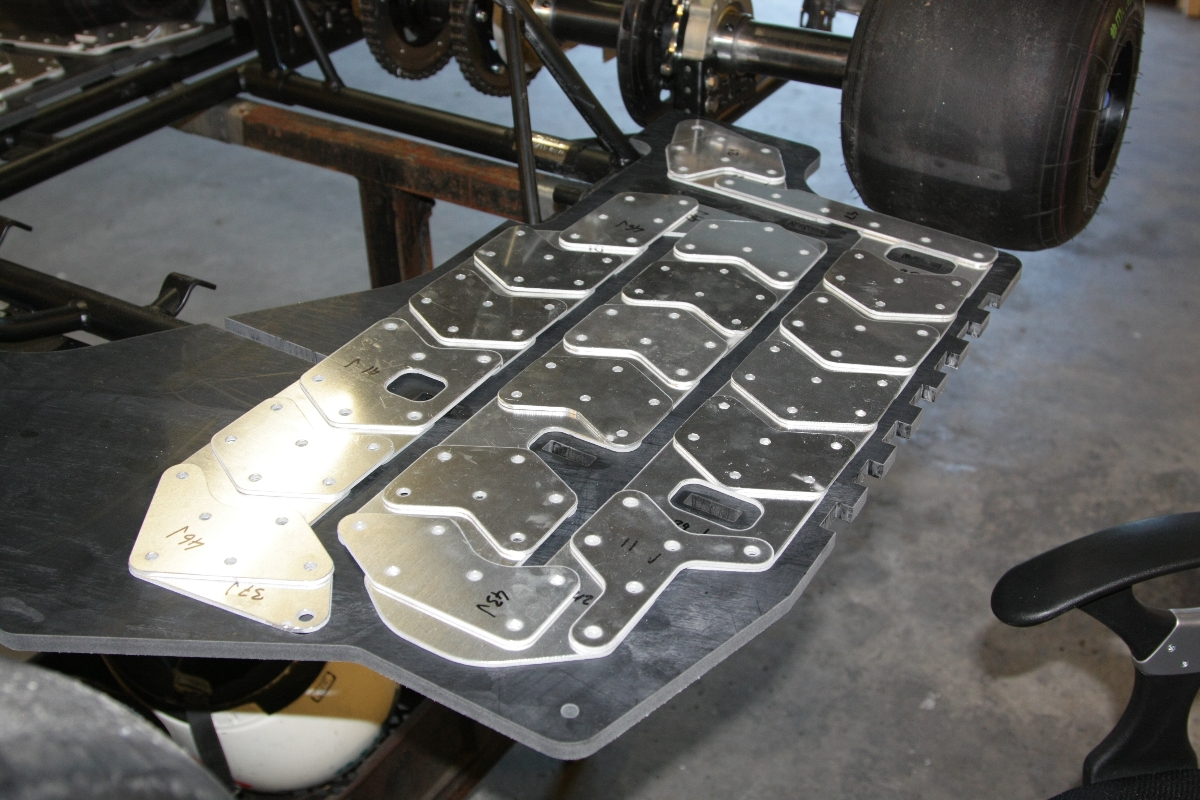

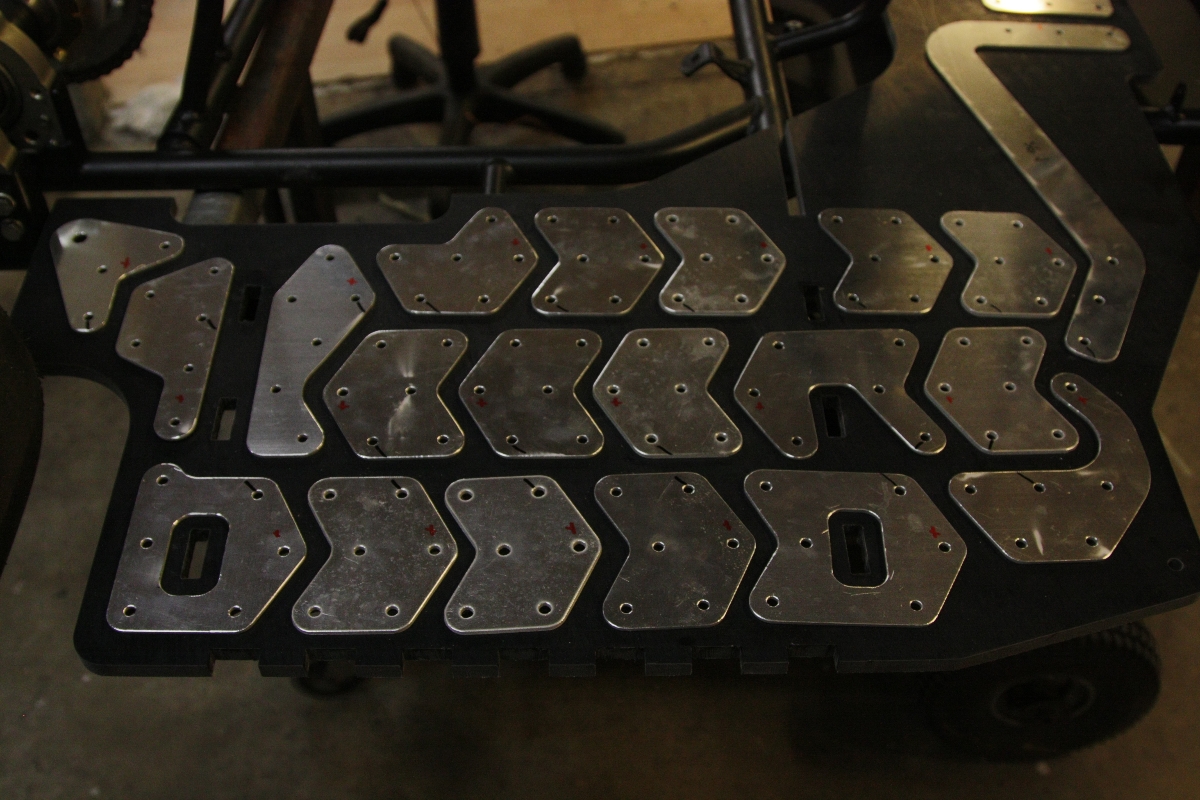

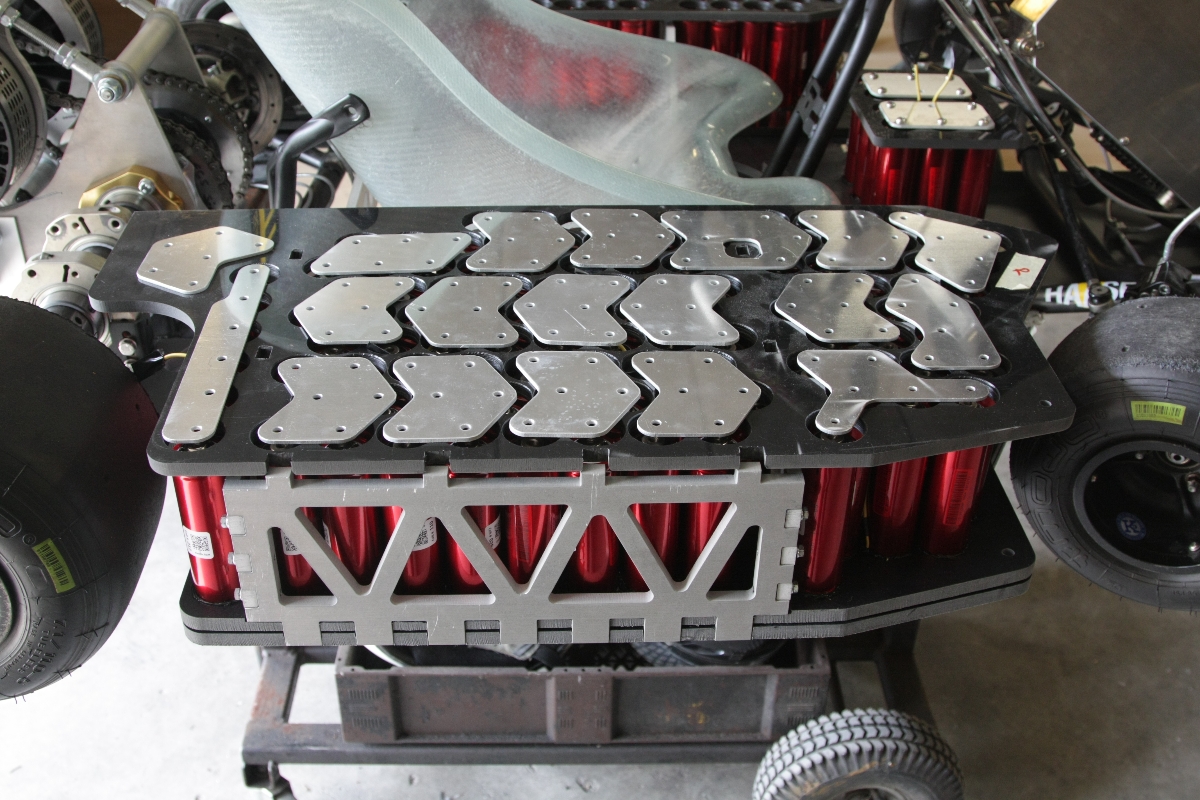

Interconnect plates between cells are made of 3 mm 1050-0 alloy aluminum. The resistivity is approximately the double of copper, but the thicker plate will still reduce the weight by a couple of kilograms when using aluminum instead of copper with same total resistance.

We want to get the lowest possible resistance as possible and have a low weight. To get lowest voltage drop and the highest output power. The total resistance of the battery pack is about 130 milli ohm.

The interconnections plates will connect the batteries in configuration of 76 cells in series and 3 in parallel, a total of 228 cells.

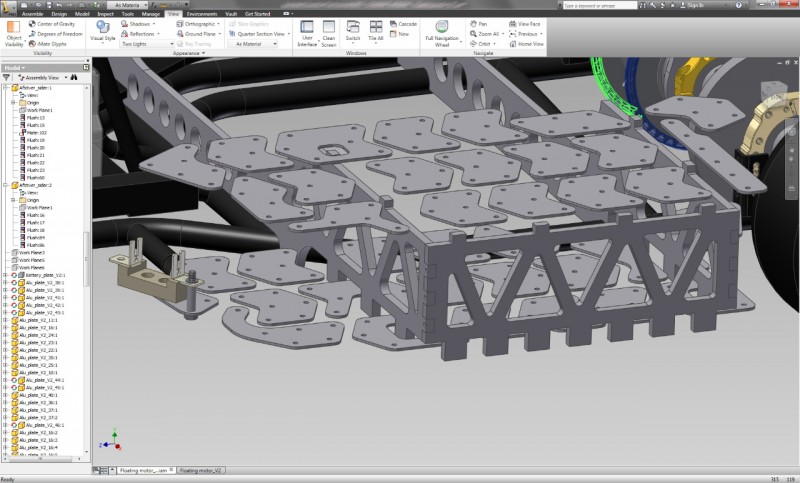

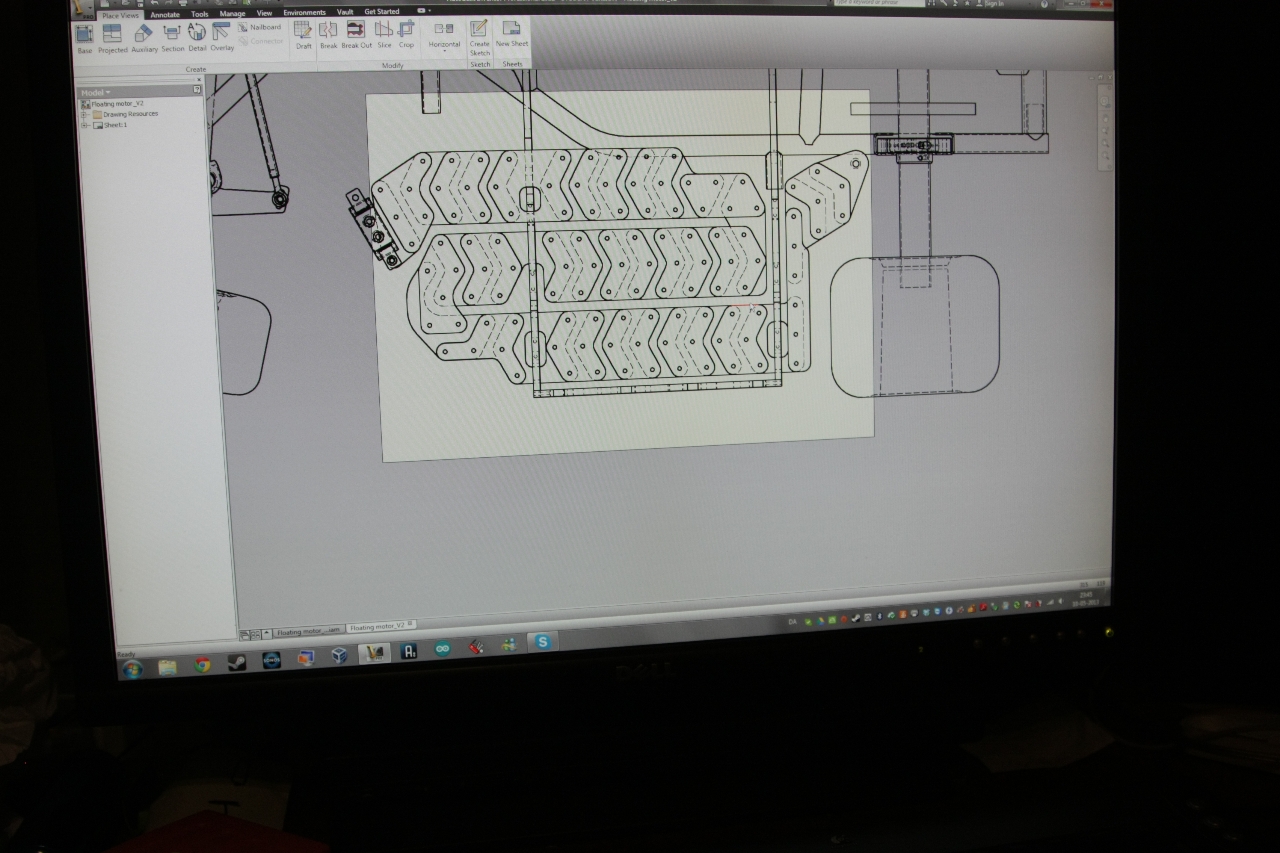

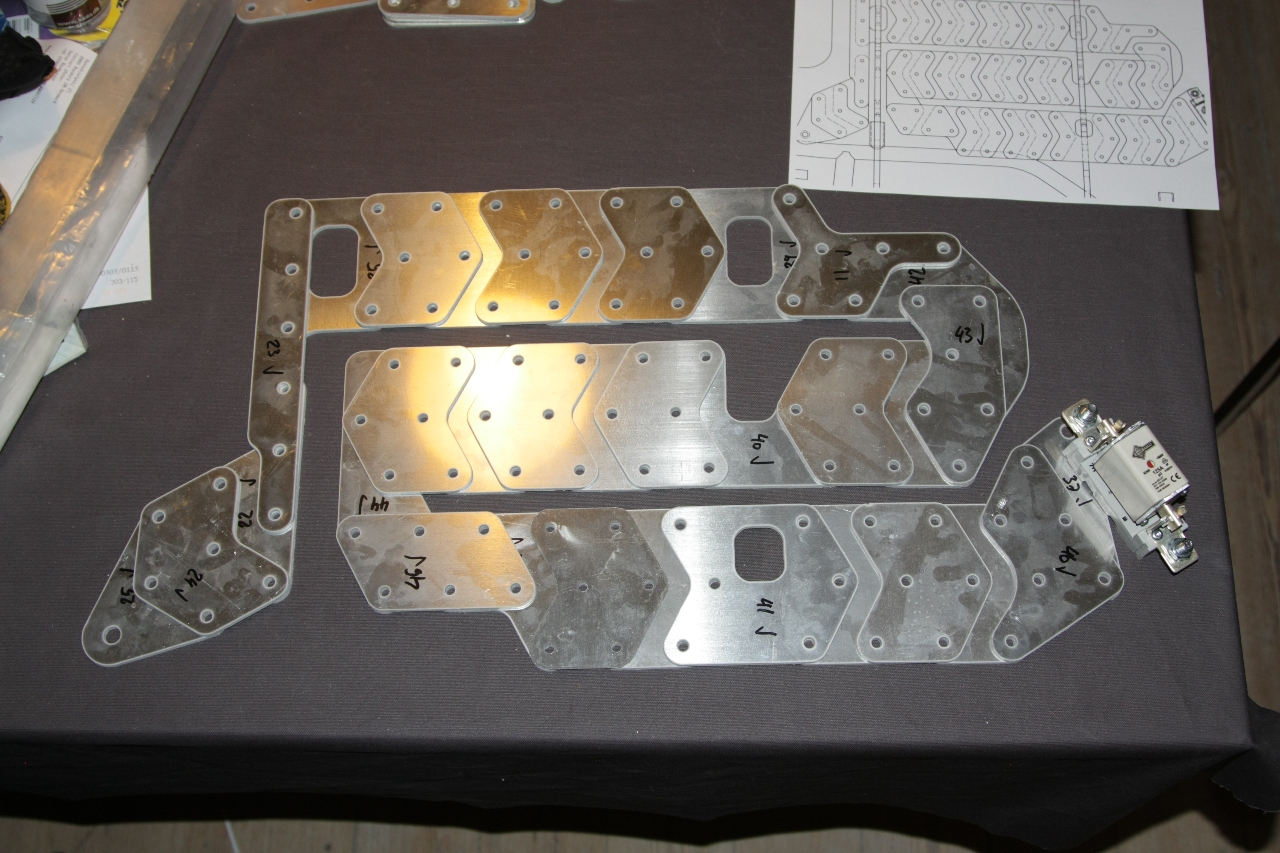

All the interconnections plates are drawn in the 3D environment. Aquacut supplied the materials and cut the parts with water.

Material specifications:

- Aluminum alloy 1050-0 = 2.810×10−8 ρ (Ω·m) at 20 °C and density 2.71 kg/m3

- Aluminum alloy 7075 = 5.388×10−8 ρ (Ω·m) at 20 °C and density 2.81 kg/m3

- Copper = 1.68×10−8 ρ (Ω·m) at 20 °C and density 8.02 kg/m3

Aluminum alloy 1050-0 have about the half resistance compared to alloy 7075. But still twice the resistance of copper but 1050-0 have a density of almost 1/4. That means that aluminium alloy 1050-0 have the best conductivity/weight ratio.

Conductivity/weight ratio (lower value are better):

- Aluminum alloy 1050-0 = 7,6151×10−8 ρ (Ω·m) at 20 °C * kg/m3

- Aluminum alloy 7075 = 15,14028×10−8 ρ (Ω·m) at 20 °C * kg/m3

- Copper = 13,776×10−8 ρ (Ω·m) at 20 °C * kg/m3