Plastic parts for battery mount and support.

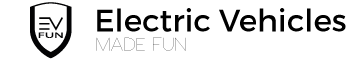

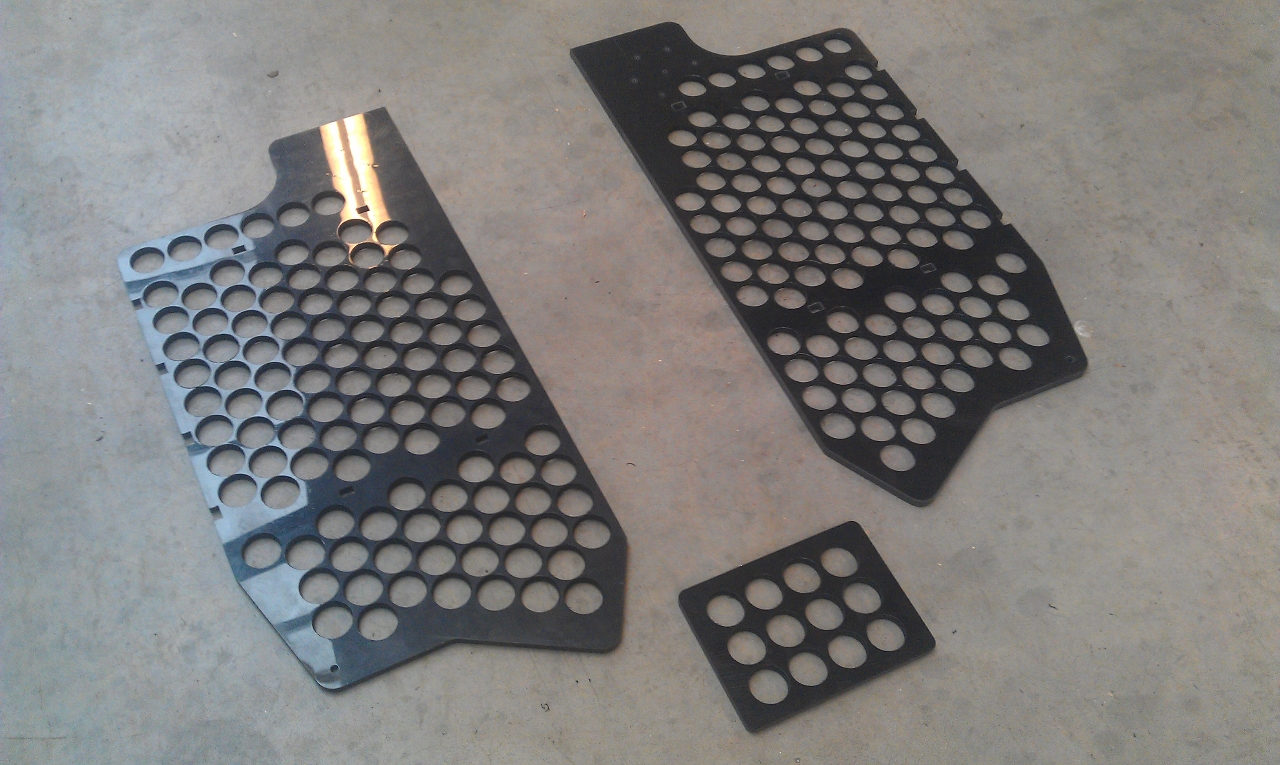

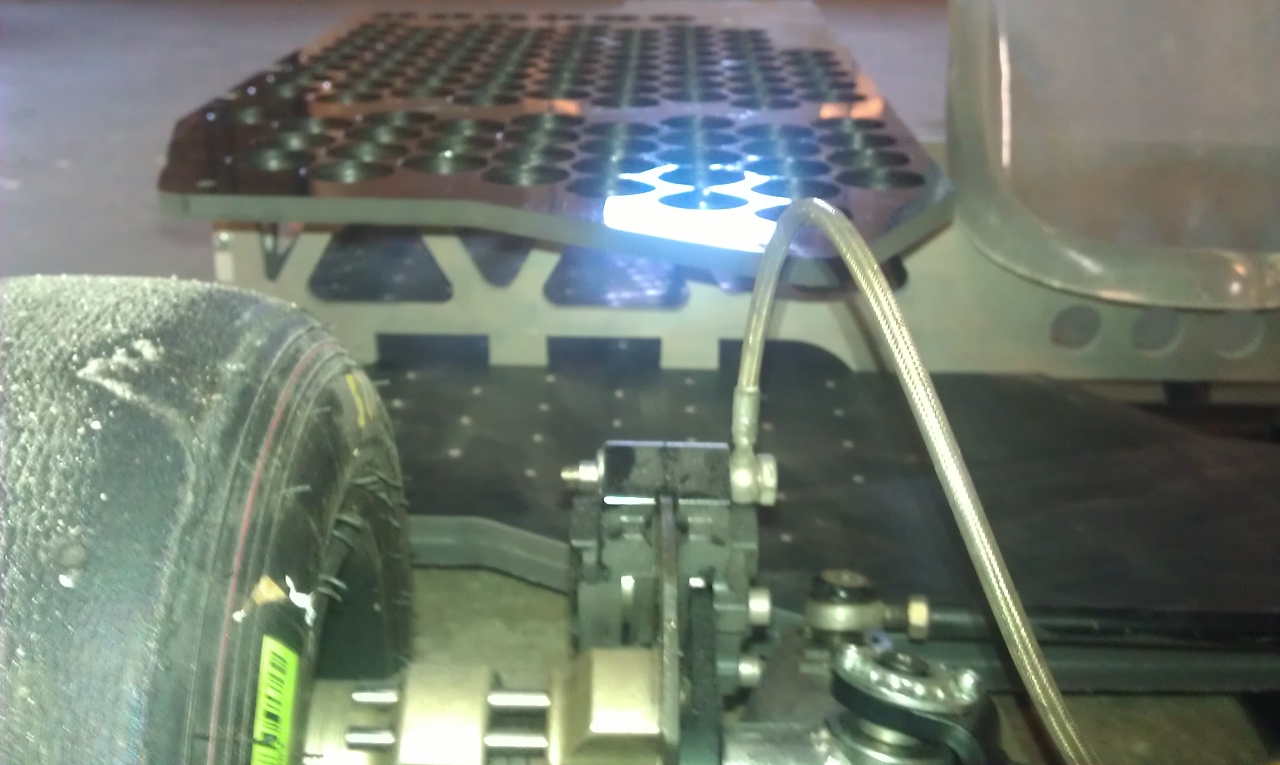

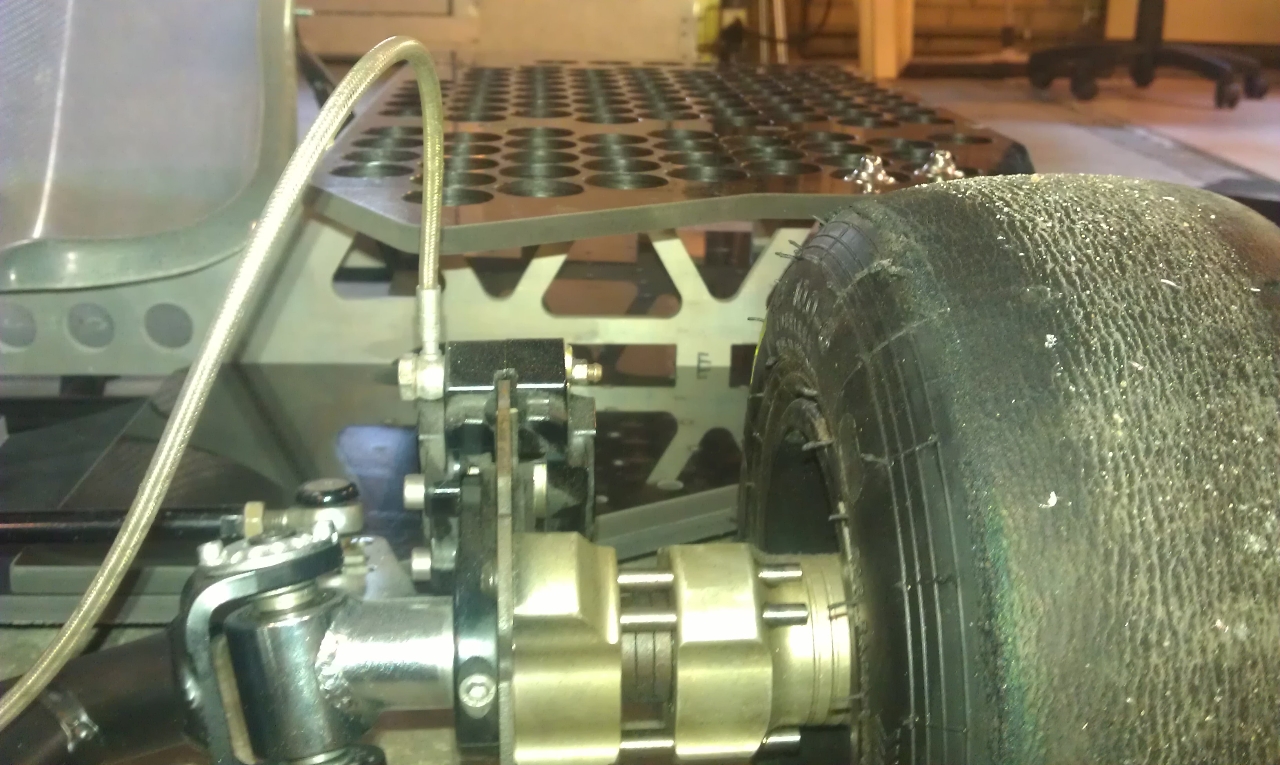

To have a strong material that not will break, did we used 11 mm nylon plates as support for the battery’s. There is three layers of nylon. Too layers at the bottom and one layer at the top. The bottom layer hides the BMS boards. Between the bottom layer and the next nylon layer, is the aluminium cell interconnections plates. The middle layer and the top layer holds the battery’s. The layout of the battery’s is made so air can pass between the battery’s in the driving direction. To make a sufficed cooling of the battery’s. Link to nylon at wikipedia.

The nylon parts interconnects with the strong aluminium alloy 7075 parts to make the battery box stiff and very robust. If you look at the pictures you can see some square hols where the parts interconnects.

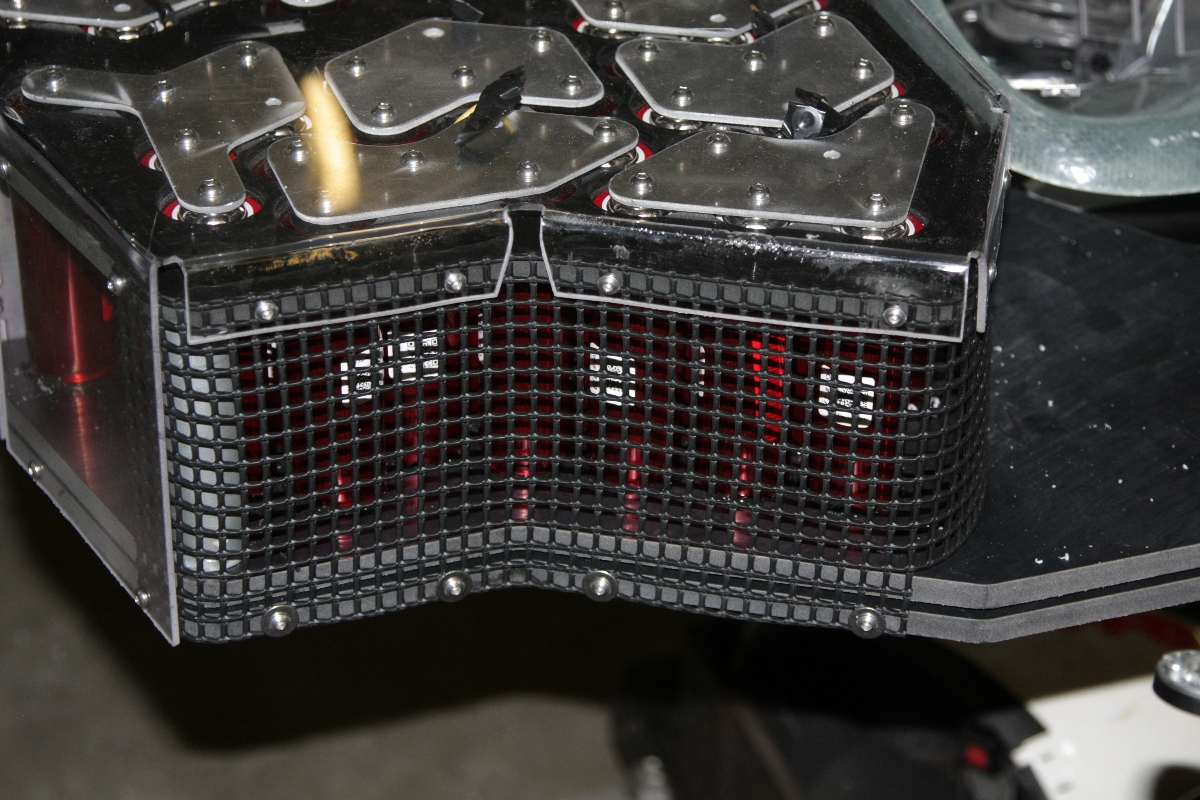

To protect against electric shock and extra strength, we used 3 mm clear polycarbonate at the top and sides. Polycarbonate is used i bullet proof glasses. Link to polycarbonate at wikipedia.

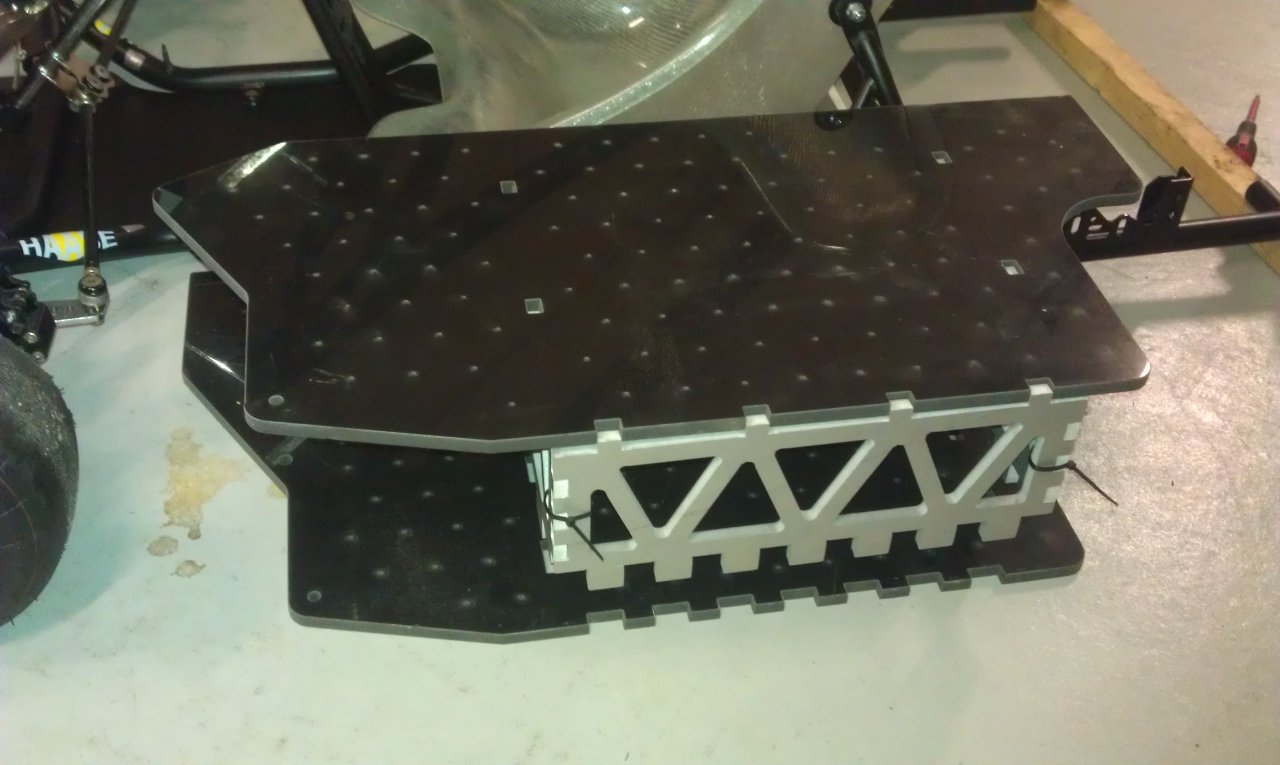

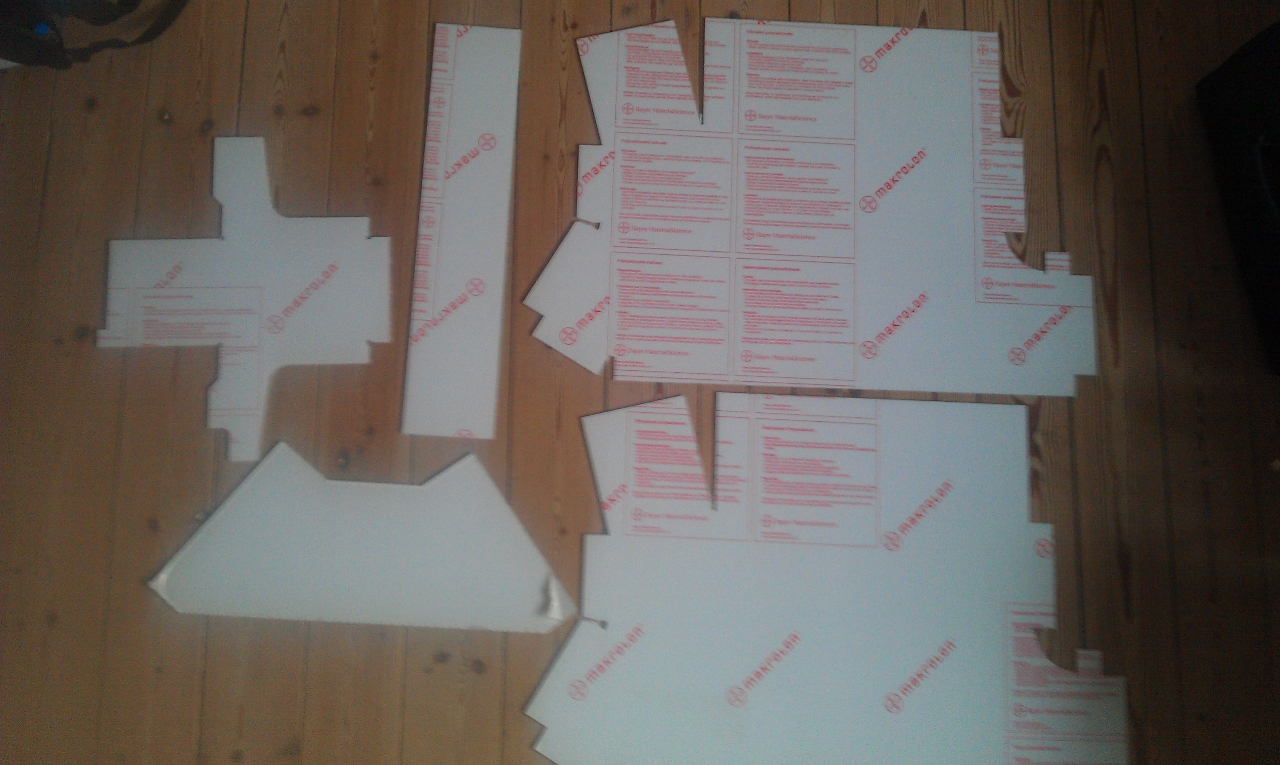

We have made the drawings i 3D and got Aquacut to water cut the parts. Excepts from the battery hols, which we only get center marked and drilled by hand. The lowering for the aluminium parts and the battery cell balance boards are also made by hand. Nylon are a tough material to drill in, when the material gets hot its sticks to everything and make a big mess.

Nylon parts: